Working site of Di Hai Machinery sand dryer machine: Application: Our three cylinder sand dryer is mainly used in dry mortar plant for drying certain humidity granular materials, such as yellow sand used in the industries of dry mortar, river sand, quartz sand, garnet sand.etc. The three cylinder sand dryer can also dry all kinds of green sand ...

Get QuoteInquiry Online

Jiangsu Leijin Environmental Engineering Co., Ltd. is a modern high-tech enterprise specializing in R&D and manufacturing of technical equipment in cement, power, metallurgy, chemical and other industries, general contracting of production line engineering, technical consultation and …

Dry Mix Mortar Equipment. Fully Automatic TDSJ 2/3/4/6/10 Dry Mixed Mortar Mixing Plant Semi-Automatic MINI Series Dry Mortar Mixer Production Line TDS Models Sand Dryer Production Line Rotary Sand Dryer Thermal Insulation Mortar Mixer Automatic Weighing Packing Sewing Machine Valve Bag Packing Machine. See all

4. About Di Hai dry mortar plant manufacturer. We are a specialized dry mortar plant manufacturing, and main products have 2-50 ton per hour dry mortar plant, tile adhesive making machine ,dry mortar mixer, sand rotary dryer, cement silo and so on. Di Hai Factory is …

Zhengzhou Corin Machinery Co., Ltd., CORINMAC Co., Ltd. is located in Zhengzhou National High New Technology Industries Development Zone, specializes in the development, manufacture and supply of dry mortar mixing equipment, industrial ...

Benin Dry Mortar Dryer Price. 2019-12-30dry mortar production line dry mortar processing flowchat dry mortar production line this dry mortar production line is composed of bucket elevator high efficiency twin shaft agravi mixer holding tank automatic packing …

Dry mortar plant is a complete dry mortar production line used to produce all kinds of mortar and plaster, which has the advantages of full computer control, high degree of automation, unique design, compact structure, simple process, energy-saving and environmental protection.

Dry Mortar Mix Production Plant. Full Automatic Dry mortar Plant; Semi Automatic Dry Mortar Plant; Simple Small Dry Mortar Plant; Wall Putty Skim Coat Mixer; Tile Adhesive Mix Machine; Dry Mortar Mixers. Multi Ribbons Screw Mixer; Twin Shafts Non-gravity Mixer; Coulter Paddle Mixer with High Speed Chopper Dispensers; Sand Dryer. Accessory ...

Drum dryers were developed to dry many food products before spray dryers came into use (Patel et al., 2009). Jack and Wasson (1940) were the first to dry the sweet whey powder using the atmospheric drum dryer. Many problems were interfered while drying the sweet whey, for instance the whey burning, browning and the loss of flow ability.

Equipments in turnkey base: Feeding Conveyor. 3 Layers Belt Dryer (2x20m conveyor x 3 layers) Exit Conveyor. Steam Boiler and Piping. Heat exchangers air handling units (3 pc) with heat recovery (rotary) Air channels and insulation. Automation and Cabling. Sand Drying Plant and screening.

Dry Mortar Plant Professional Dry Mortar Plant / MG series Pre - Mixed Dry Mortar Mixer Machine Full Automatic Dry Mortar Production Line For Cement Sand Mixing Horizontal Putty Dry Mortar Plant Various Output Carbon Steel Small Spiral Ribbon Mixer Dry Mix Plant High Quality Large Capacity 30T Per Hour Full Automatic Dry Mix Plant

Three cylinder dryer which newly developed by MIND, apply to dry-mixed mortar, sand, cement plant slag, coal gangue, slag, mixture, coal ash, gypsum, iron powder and other raw material’s drying. It widely used in building materials, chemical industry, foundry and other industries.

MG series three cylinder sand dryer is produced with three different diameter homocentric cylinder according to the certain mathematical relationship and cylinder structure then combinated by embedded with each another. MG series single cylinder drum dryer is a kind of rotating continuous drying equipment with internal heating conducting-style.

Dry Mortar Plant Professional Dry Mortar Plant / MG series Pre - Mixed Dry Mortar Mixer Machine Full Automatic Dry Mortar Production Line For Cement Sand Mixing Horizontal Putty Dry Mortar Plant Various Output Carbon Steel Small Spiral Ribbon Mixer Dry Mix Plant High Quality Large Capacity 30T Per Hour Full Automatic Dry Mix Plant

Henan Mind Machinery Equipment Co., Ltd. is a professional manufacturer of mining, crushing, screening and drying equipments, with a long-term supply of ore dressing and gravel aggregate industries with crushers, vibrating screens, washing equipments and belt conveyors, etc. Mind Machinery persists in providing highly customized solutions according to different requirements, including single ...

Dry Mixed Mortar Plant. Production Capacity: 200,000-500,000 tons per year Component Parts: Material storage tank, sand dryer, batching apparatus, mixer, dry powder packing machine, dust collector and conveyor. Application Fields: To produce single component and multiple component mortar products such as dry-mixed mortar, water proof mortar, adhesive mortar, plaster anti-crack mortar and ...

NFLG's main business scope covers mine mining design, construction material mining and crushing, screening, shaping, machine-made sand production lines, solid waste treatment equipment, engineering mixing equipment industrial chain, comprehensive solutions, etc., is a long-term focus on mixing An international professional company for equipment R&D, manufacturing and services.

Apr 27, 2020 In April 2020, one set Aimix sand dryer starts to work in Indonesia. This is a video took on the working site of Aimix 50 ton sand dryer. Sand dryer can work independently. It is also usually adopted in a dry mortar production line or tile adhesive manufacturing plant, for the heating and drying of wet sand. This sand dryer adopts triple-pass design, which has much higher drying efficiency ...

Total price: $30.99. Add both to Cart Add both to List. One of these items ships sooner than the other. Show details. Buy the selected items together. This item: Dryer Heating Element for Samsung, DC47-00019A $19.50. Only 5 left in stock - order soon. Sold by OKS Market and ships from Amazon Fulfillment.

Dry Mortar Mix Plant, Triple Drum Dryer, Bucket Elevator manufacturer / supplier in China, offering Prefab Steel Structures Steel Building Steel Houese, Two Story Steel Structure Warehouse Steel Prefab Building, Wholesale Customized Industrial Steel Structure Series …

This mixer is specially designed for dry mortar and works with dry materials in powder, granules and sticky materials. High wear resistance; Extremely low maintenance; Specially designed for dry mortar mixing; Hydraulic and pneumatic operated discharge doors; Wide range of models from 200 to 6,000 litres | 1/4 yd 3 8 yd 3 output

Rotary Dryer. Power: 7.5-75kw Processing Capacity: 10-30TPH Applied Materials: Slag, blast furnace slag, fly ash, cinder, slag, carbide slag, limestone, clay, sand, quartz sand, etc. Magnetic Separator. Feeding Granularity: 0-3mm Production Capacity: 10-280TPH Applicable Range: it is suitable for the magnetite, pyrrhotite, roasted ore, ilmenite and other materials smaller than 3mm in wet-type ...

Dry Mixed Mortar Plant. Dry mixed mortar plant is designed for enterprises which have small production scale of special dry mortar. It is a kind of modular production line which can meet the needs of producing multiple species dry mixed mortar and ordinary mortar in small bat. Details

1, the dryer is less investment, my company sand dryer is the most preferential, price 20% of imported products, highest performance-to-price ratio. 2, Our company sand dryer wear-resisting degree is high, is made of wear resistant manganese plate manufacturing , than ordinary steel wear-resisting 3-4 times.

General Product Type Front Load Dryer Dryer Capacity 10 Kg Color White Measurements Height 845mm Width 600mm Depth 659mm Features Wash Programmes 6th sense,steam care Special Features 10 Kg Condenser drer,B class energy efficiency,68dB noise level,eco monitor,steam care option,start dely,adjustable dryness level,anti crease function,start delay option continuous,finish on …

MG series sand dryer and dry mortar machine with CE and ISO certificate, has exported to more than 30 countries until now. We warmly welcome the client worldwide come to our factory for study and cooperation on the dry mortar production line.

The CHI 1875 Series Hair Dryer features ceramic ions that safely dry hair while reducing frizz and adding shine; Variable heat and speed settings are perfect for all hair types and textures; Includes a nozzle concentrator to add volume or smoothness to blow outs

dryer can dry up to 300 pounds of food per month~ a large dryer can dry up to 6,000 pounds a month~ and a very large system can dryas much as lO,OOC or more pounds a month. (Figures are based on harvests in tempe~ate climates.) Figure 2 shows the breakdown, by type, of solar food dryers. ~ PASSIVE SOLAR FOOD, DRYERS,, f

Jan 27, 2015 The melting of the fibers is what is going to keep the balls from unraveling in your dryer. With time, the wool balls will continue to felt and get slightly smaller. So, I use all 6 balls in the dryer. They have consistently cut my regular drying time in half. What used to take 70 minutes to dry …

Dry Mortar Dryer,Dry Mortar Dryer price,Dry Mortar Dryer. Dry mortar dryer is mainly used for drying materials with certain humidity and particle sizes such as sand, slag, cinders, small particle size of clay and high temperature resistance materials with small particle size. After the drying operation, the water content reaches as low as 1-0.5%.

Dry Mortar Mix Plant; Dry Mortar Mixer; Dryer Machine; Cement Silo; Paint Mixer; Packing Machine; Dust Collector; Convey System; Part; ABOUT US; ... Rotary Dryer slladmin 2018-05-29T09:34:16+00:00 Products list. Dry Mortar Mix Plant; Dryer Machine; Paint Mixer; Cement Silo; Concrete mixer; Convey System; Dust Collector; Packing Machine; Part ...

Dry Mortar High Mixing Coulter mixer Dry mortar mixer . High mixing capacity dry mixed mortar equipments , by the driving wheel reducer shaft drives the coulter group movement, on the one hand, the material along the radial circumferential turbulent cylinder circumference of a circle, at the same time the material along the normal direction on both sides of the coulter throw, on the other hand ...

Martins Washer and Dryer Service LLC is a in the home repair service for domestic clothes washers and dryers.My fee is a flat fee of $80.00 no hourly fee-no minute fee-no arrival fee- no transit fee.so it will cost you $80.00 pulse the cost of parts to fix your washer or dryer.A simplified pricing system that you can understand easily = $80.00 pulse parts.

Rotar sand dryer can ensure that the final moisture of the material is below 0.5%, which is the first choice for dry mortar plant and slag powder. Sand Drying Plant Triple pass rotary drum dryer with hot blast heater, discharging hopper, blower pipe, cyclone dust collector, belt conveyor and induced draft fan form a sand drying plant.

Getting started; Dryer Machine; Dryer Machine - China Factory, Suppliers, Manufacturers. We are experienced manufacturer. Wining the majority from the crucial certifications of its market for Dryer Machine, Premixed Brick Mortar Plant, Dry Sand Making Machine, Dust Cleaning Machine,Concrete Cement Silo.We maintain timely delivery schedules, impressive designs, high-quality and …

Alibaba.com offers 1,224 dry mortar dryer machine products. A wide variety of dry mortar dryer machine options are available to you, such as warranty of core components, local service location, and key selling points.

Short Description: Dryer machine can be also called drum dryer, or dryer drum or rotary dryer machine, etc, it is a kind of drying equipment widely used in mining system,dry mix mortar plant etc. This kind of dryer mainly applicable for drying wet material within certain range humidity. 1) Use widely with high quality and simple structure.

Sand dryer is one of the spare parts in dry mix mortar plant.Its main function is to dry the water in the yellow sand (The initial moisture after drying is about 8%) and get the dried sand (final moisture ≤ 0.5%), adjust the temperature in the grading and conveying process of dry sand, ensure that the sand enters the storage silo with a temperature≤ 60℃, so as not to affect the quality ...

I'm assuming the shed need to get an hot air (or exhaust gases from the rocket) inlet and an exhaust to vent the moist outside. There's a problem in this respect, wood combustion produces water as a byproduct, close to 1/2 liter for every kilogram of fuel. Adding this to the process means the wood or food is expected to dry by adding moist hot air.

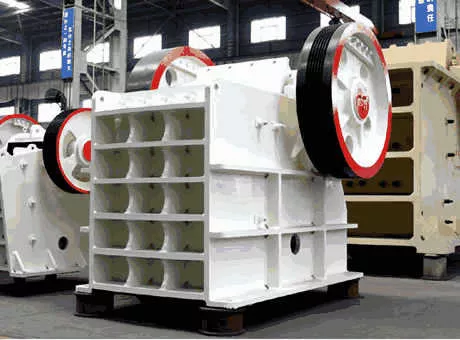

price list of stone crusher in kenya

price list of stone crusher in kenya

term paper on limestone crushing mpany in togo essaydepot

term paper on limestone crushing mpany in togo essaydepot

metal crusher in ukraine

metal crusher in ukraine

crusher machine rental in ukraine

crusher machine rental in ukraine

what is cost of waste crusher in philippines

what is cost of waste crusher in philippines

gypsum crushing machine in india shanghai zenith company

gypsum crushing machine in india shanghai zenith company

mining secondhand equipment exporters in zimbabwe

mining secondhand equipment exporters in zimbabwe

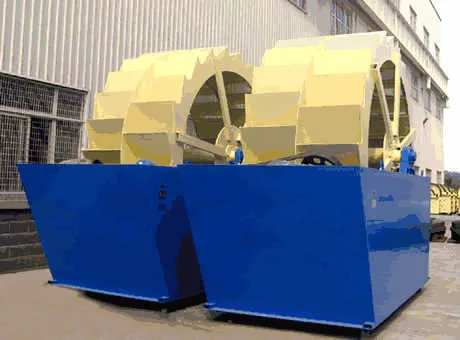

sand washing machine in egypt

sand washing machine in egypt

Request A Quote

We believe that customer service comes first.

More than 600 large and medium-sized digital processing equipment

More than 2,300 front-line technicians and after-sales service personnel